NEWS RELEASES

Products and Technology

Mazda Cuts Precious Metal Usage 70 Percent in New Single-nanocatalyst

- World first commercial application of the new catalyst will be in the all-new Mazda3 and progressively introduced to other models -

|

HIROSHIMA, Japan—Mazda Motor Corporation has announced the world’s first market application of single-nanocatalyst* technology in automobile catalytic converters. This highly durable new catalyst significantly reduces the amount of precious metals used and effectively purifies vehicle exhaust gases. It will first be introduced in the all-new Mazda3 (known as the Mazda Axela in Japan) which will commence global sales this year.

With the single-nanocatalyst, the underfloor catalytic converter in the all-new Mazda3 requires only 0.15g/L of precious metals, approximately 70 percent less than the 0.55g/L required in the previous model. Along with the substantial reduction in precious metal usage, the Mazda3 continues to qualify as a Super Ultra-Low Emissions Vehicle (SU-LEV) in Japan by achieving exhaust emissions that are at least 75 percent cleaner than the government’s 2005 regulations.

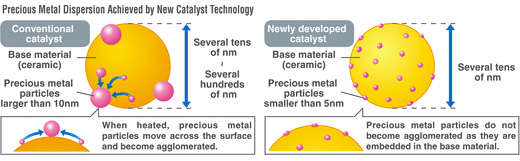

Automotive catalysts consist of a base material coated with precious metal particles. These metals promote chemical reactions that purify exhaust gases. In conventional catalysts, exposure to hot exhaust gases causes the precious metal particles to agglomerate into larger clumps, which reduces their effective surface area and catalytic activity. To counteract this, an increased amount of the precious metals is required to maintain an efficient purification performance.

Mazda developed the single-nanocatalyst to increase the effective surface area of the precious metals used. By developing a method of controlling precious metal particles that are less than five nanometers (nm) in diameter as well as a proprietary catalyst material structure, Mazda created the world’s first catalyst that features single-nanosized precious metal particles embedded in fixed positions. As a result, there is no agglomeration of the particles and the amount of rare metals used can be significantly reduced. Moreover, the new catalyst material will enable very efficient purification with minimal deterioration over time even under the harshest operating conditions.

Going forward, Mazda will progressively introduce the single-nanocatalyst to all its global markets, which will contribute to a reduction in the consumption of rare metals and cleaner vehicle exhaust emissions.

|